ABSTRACT

Background:

Wound healing is a complex and dynamic process of restoring cellular structures and tissue layers. The aim of the present investigation was formulation and optimization of instant film forming thermoreversible chitosan hydrogel for wound healing.

Materials and Methods:

A novel hydrogel composing of chitosan, Ethanol, Sodium α-β Glycerophosphate and combination of three drugs (Ascorbic acid, Tuftsin, Zn gluconate) were prepared. Ethanol and α-β Glycerophosphate (α-β-GP) were selected based on gelling time and film formation time. Optimization of vehicle in formulation was done by using 32 full factorial design using Design Expert® 8.0.7.1 software. Optimization of drug loaded thermoreversible chitosan hydrogel was done with 0.2mg, 2mg, 20mg, ratio of Zn gluconate, Tuftsin (10 μg/mL), Ascorbic acid (0.1mg/ mL) by trial-and-error method.

Results and Conclusion:

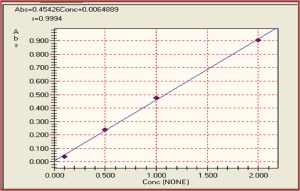

The Gelling time, Film formation time, swelling ratio and Moisture retention capacity of the optimize drug loaded formulation (X2) were 160±19.5, 390±18.4, 296±7.58, 6.8±0.76 respectively. The in vitro release of optimize drug loaded hydrogel formulation was carried out by Franz diffusion cell. In vitro drug release data of optimize batch was 86.5+1.9%, 80.66±4.52, 85.55±2.95 in 24 hr for Ascorbic acid, Tuftsin, Zn gluconate respectively. Chitosan hydrogel showed powerful antibacterial efficacy up to 100% to Staphylococcus aureus (ATCC 29213) and Escherichia coli (ATCC 87064) by hydrogel formulation with or without drug. Since the formulation contains thermosensitive drugs stability study of optimized batch was carried out as per ICH guidelines. The stability data shows that the optimized batch of thermoreversible chitosan hydrogel remains stable for 1 month-controlled room temperature (25°C±2°C/ 60%RH±5%RH) and refrigerated condition (5°C±3°C). In vivo studies also carried out.